Mig welding process fmea 82onecritiziseme mig welding process fmea gas metal arc welding gmaw sometimes referred to by its subtypes metal inert gas mig welding or metal active gas mag welding is a welding process in which an electric arc forms between a consumable mig mig welding process fmea chateiland nl.

Sheet metal fmea.

Fmea worksheet failure mode and effects analysis sheet the fmea worksheet failure mode and effects analysis supports the process of managing the risk associated with product or process failures.

Click image to get our fmea failure mode and effects analysis worksheet.

Sheet metal cuttingis a major classification for many different pressworking operations.

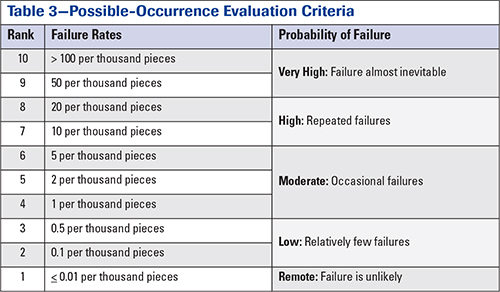

Fmea scales for severity occurrence detection severity scale for failure modes effects s cale of 1 least severe to 10 most severe for each effect occurrence scale for potential root causes s cale of 1 least frequent to 10 most frequent for each root cause minor rank 1 low rank 2 3 moderate rank 4 6 high rank 7 8 very high rank 9 10.

Terms in the sheet metal industry stamping higher strength steels seminar sept 12 13 in nashville fmea failure modes effects analysis in sheet metal forming.

Sheet metal varies in thickness.

This separation is caused by shearing forces acting on the metal through the edges of the punch and die.

Failures come in all degrees with some more important than others.

Sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions.

Failure modes effects analysis in sheet metal forming scrambling to fix production problems can lead to a host of other issues.

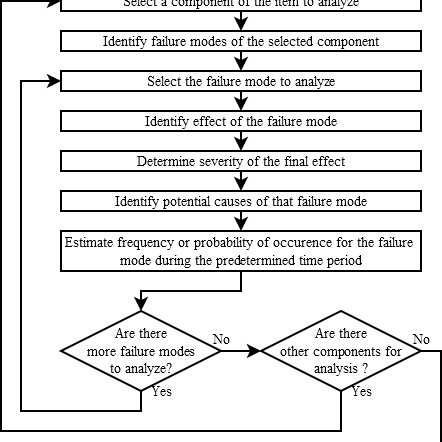

Definition of fmea failure mode and effects analysis fmea is a method designed to.

Pressworking a term referencing sheet metal operations in general.

A wide range of products are manufactured with the use of sheet metal making it an essential part of the modern world.

Fmea or failure modes and effects analysis can help align your efforts with the issues that can cause the most headaches.

Identify and fully understand potential failure modes and their causes and the effects of failure on the system or end users for a given product or process.