Sheet metal forming services circle grid analysis and thickness strain analysis thinning and circle grid surface strain analyses are engineering quality tools that can help determine where trouble spots could develop during the production processing of your parts.

Sheet metal forming report.

Involves workpieces with a high ratio of surface area to thickness.

The content of this report includes an overview about the whole manufacturing fundamentals and the processes to be followed in this category in order to obtain the required final product.

Plates thickness inch.

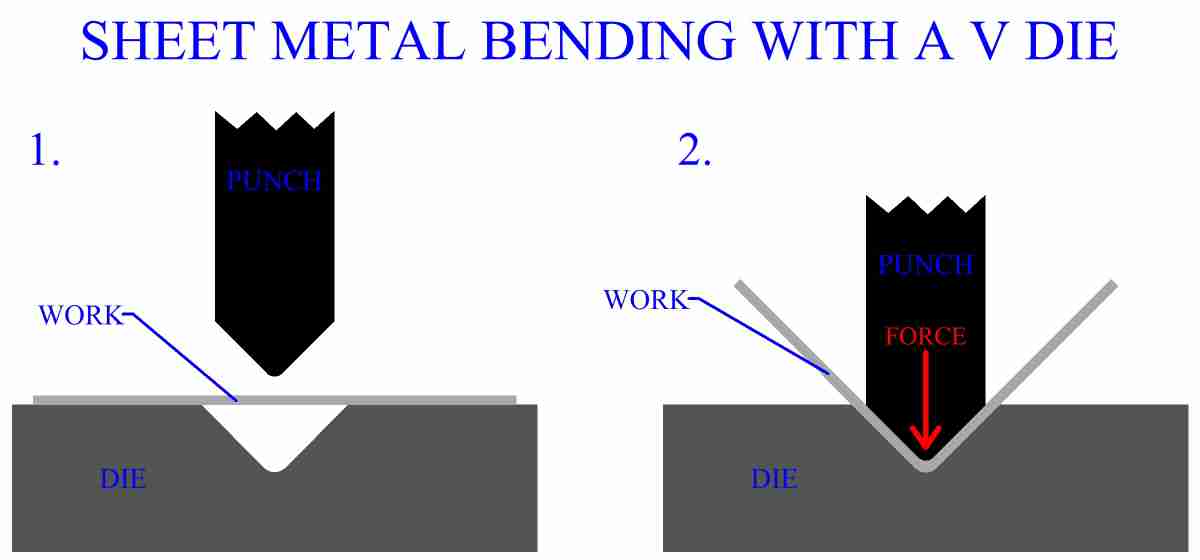

The sheet metal takes the form of the design cut into the die.

Sheet metal forming is quite common for making shaped components from soda cans to automotive car bodies.

M p groover fundamentals of modern manufacturing 3 e figure 20 1 shearing of sheet metal between two cutting edges.

1 just before the punch contacts work.

Sheets thickness inch.

The knowledge of sheet metal fabrication is very useful in our day to day life and one needs to know at least the basics of the same.

Gravity fall the blank adapts to the blankholder shape blankholder punch original flat blank gravity deformed blank holding the die pushes on the blankholder and squeezes the blank.

Most problems in sheet metal forming come from a bad control of holding restraining and springback.

Metal desks appliance bodies.

Drawing forming of sheet into convex or concave shapes 7.

2 punch begins to push into work causing plastic deformation.

Sheet metal forming processes.

Sheet metal forming press has been explained to clarify each phase of the technique adopted by suppliers in the metalworking industry.

Hydraulic die forming is quicker and lends itself more to duplicating formed art or other production.

In both sheet metal is sunk or pressed into a die.

This report elaborates the recent advancements in the process of sheet metal forming in automotive industry since this technique is considered as one of the most important issues in the current industry.

Sheet metal cutting 8.

Chap 2 sheet metal p.

Hydraulic die forming is somewhat similar to masonite die forming.

2007 john wiley sons inc.

It provides an expanded and more comprehensive treatment of sheet metal forming processes while placing forming processes and die design in the broader context of the techniques of press working sheet metal.

Typical items produced by sheet metal forming processes.