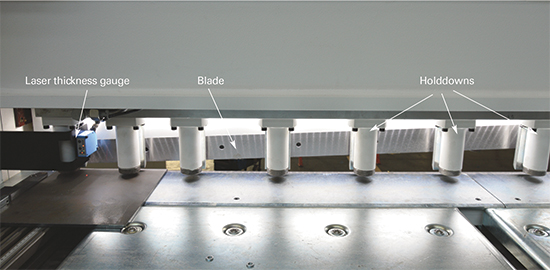

Slitting is a shearing process in which the sheet metal is cut by two opposing circular blades like a can opener.

Sheet metal forming shearing and cutting process.

The metal shearing process can be used with virtually any diameter part and is especially cost effective for high output operations producing thousands of pieces per hour.

The sheet metal blanking process is a one of the shearing operation.

The shearing process characteristics include.

The most commonly sheared materials are in the form of sheet metal or plates however rods can also be sheared.

When the blanking of sheet metal process the removal of piece is called as blank.

The symmetrical parts can be formed over mandrels by using sheet metal spinning process.

Slitting can be performed in a straight line or on a curved path.

The most common cutting processes are performed by applying a shearing force and are therefore sometimes referred to as shearing processes.

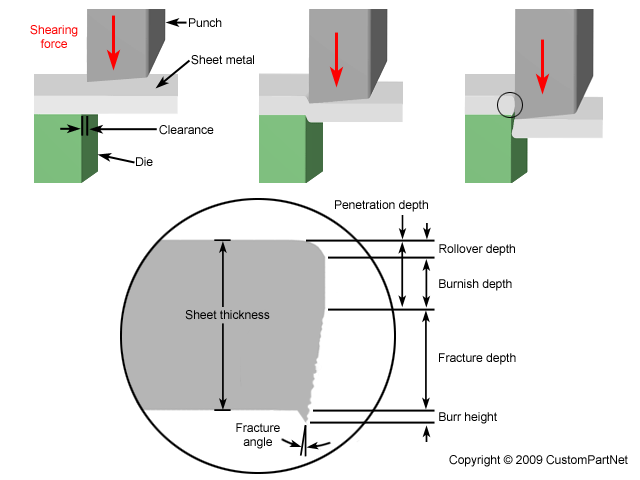

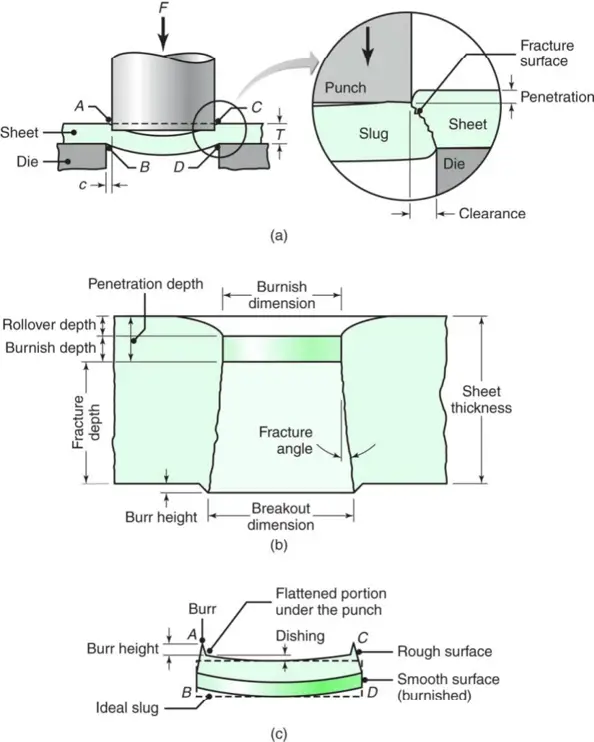

2 punch pushes into work causing plastic.

It is used in.

Shearing is a metal fabricating process used to cut straight lines on flat metal stock.

Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to caused the material to fail.

The circular sheet metal cutters can be driven or the work may be pulled through idle cutters.

Normally one of the blades remains stationary.

Cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in thick plate stock 6 mm thick advantage high strength good dimensional accuracy good surface finish economical mass production low cost.

Its ability to make straight line cuts on flat sheet stock.

The axis symmetric components formed by using spinning sheet metal forming as shown in figure the spinning metal product such as aircraft engine parts jet engine parts truck wheels and etc.

Slitting usually produces a burr that must be removed.

If the cutting blades are curved then they are shearing type operations.

Blanking piercing roll slitting and trimming.

The rotation of sheet metal with high speed on a spinning lathe.

Part of the fundamental manufacturing processes video series this program examines two of the oldest manufacturing processes.

Shearing also known as die cutting is a process which cuts stock without the formation of chips or the use of burning or melting.

During the shearing process an upper blade and a lower blade are forced past each other with the space between them determined by a required offset.

Nc state university sheet metalworking terminology punch and die tooling to perform cutting bending and drawing stamping press machine tool that performs most sheet metal operations stampings sheet metal products 1 just before punch.

Strictly speaking if the cutting blades are straight the process is called shearing.